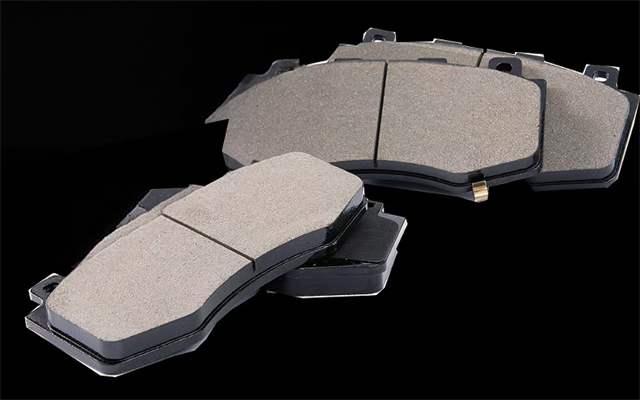

Main roles of brown corundum wear-resistant sand /powder play in producing brake pads

Brown corundum wear-resistant sand/powder is made of high-quality bauxite and is smelted at 2000℃ in an electric arc furnace. It is de-ironized by jaw crusher, grinder, magnetic separation, and sieved into various particle sizes. Its wear-resistant powder is made by pickling, washing, overflow classification, and has high cleanliness and concentrated particle size. It is mainly used for sandblasting, grinding, polishing, ceramics, coatings, wear-resistant products, etc.

Brown corundum wear-resistant sand/ powder can play the following roles in the production of brake pads:

1. Enhance wear resistance and hardness

The hardness of brown corundum wear-resistant sand /powder is second only to diamond. After adding it to the brake pad, its surface hardness is significantly improved, which effectively resists wear during braking, prolongs service life, and reduces replacement frequency and maintenance costs.

2. Increase friction coefficient

The particle structure of brown corundum wear-resistant sand/powder can increase the friction between the brake pad and the brake disc, shorten the braking distance, and improve the response speed and safety of the vehicle during emergency braking.

3. Maintain high temperature stability

The high temperature generated by friction during braking can easily cause material deformation or performance degradation. Brown corundum wear-resistant sand /powder has strong heat resistance (can withstand high temperatures over 1000℃), ensuring that the brake pads maintain shape stability and braking performance at high temperatures.

4. Improve corrosion resistance

In humid, salt-corroded or oily environments, brown corundum wear-resistant sand /powder can slow down the corrosion rate of brake pads, avoid performance degradation caused by environmental erosion, and further extend service life.

Brown corundum wear-resistant sand /powder sizes

Brown corundum wear-resistant sand/ powder is usually evenly mixed into the brake pad matrix material in the form of micropowder and macrogrits. Due to its diverse particle size and narrow span, it synergizes with other ingredients (such as resin adhesives, reinforcing fibers, etc.) to optimize comprehensive performance.

Haixu Abrasive Factory produces the following brown corundum wear-resistant sand:

JIS standard: #12 #14 #16 #20 #24 #30 #36 #46 #54 #60 #70 #80 #90 #100 #120 #150 #180 #220 #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000

FEPA standard: F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220 F230 F240 F280 F320 F360 F400 F500 F600 F800

P standard: P12 P16 P20 P24 P30 P36 P40 P50 P60 P80 P100 P120 P150 P180 P220 P240 P280 P320 P360 P400 P500 P600 P800 P1000 P1200 P1500 P2000 P2500 P3000

Conclusion: Brown corundum wear-resistant sand/powder has become a key functional material for improving the durability, safety and environmental adaptability of brake pads by enhancing hardness, friction, heat resistance and corrosion resistance.