What is brown corundum as a wear-resistant filler used for?

As a high-performance wear-resistant filler, brown corundum is mainly used in the following product areas:

I. Transportation field

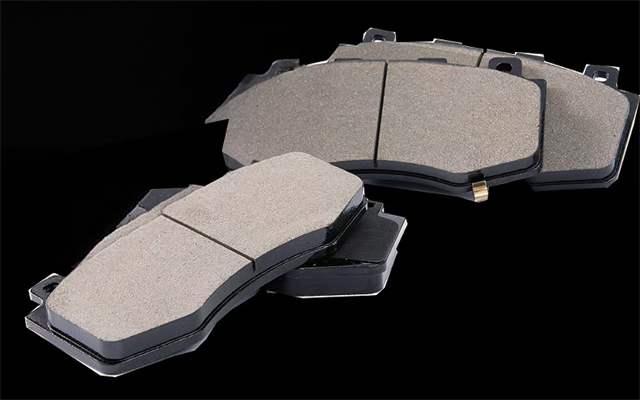

Automobile brake parts: Brown corundum is used as a brake pad/brake disc reinforcement filler to improve wear resistance and high temperature stability and extend service life.

Special tires: Brown corundum is used for the tread of engineering vehicle tires to enhance wear resistance and adaptability to harsh road conditions.

Transportation facilities: Brown corundum is used as a wear-resistant layer material for highway pavements, airport runways, and dock floors.

Brown corundum is added to the wear-resistant coating of parking lots to improve compression resistance and durability.

II. Construction and industrial fields

Special building products: Brown corundum is used as a high-wear-resistant concrete additive (such as industrial floors and sports venues).

Brown corundum is used as a filler for tile adhesives to improve impact resistance and structural stability.

Industrial wear-resistant materials: Brown corundum is used as a protective coating for heavy machinery and a filler for wear-resistant parts of mining equipment.

Brown corundum is added to the corrosion-resistant and wear-resistant lining of chemical equipment.

Brown corundum is the main material for producing grinding wheels, cutting discs, polishing blocks, etc.

Ⅲ. Other fields

Sports facilities: Adding brown corundum to wear-resistant floor coatings such as running tracks and stadiums to improve wear resistance and extend service life.

Refractory auxiliary: Adding brown corundum to some refractory bricks/casting materials to enhance wear resistance.